Each plant has a purpose. Lets take a look at some of the oldest ones to the new ones.

🌿 Castor Plant – Nature’s High-Performance Oil

The castor plant (Ricinus communis) has been cultivated for over 6,000 years, from ancient Egyptian lamp fuel to modern aerospace lubricants. Its seeds produce a uniquely rich oil—composed of over 90% ricinoleic acid—making it one of the most chemically versatile plant oils on Earth.

At ABOVE, we value castor oil for its:

- Extreme pressure tolerance – ideal for high-stress machinery and racing applications.

- Biodegradability – a sustainable alternative to petroleum lubricants.

- Compatibility – serves as a base for bio-plastics, esters, and performance additives.

Castor is a low-water, high-yield crop that grows well in semi-arid regions, and its oil serves as the foundation for cutting-edge green chemistry and AI-designed lubricants.

From Pharaohs to Formula One—castor oil proves nature’s engineering can go the distance.

Yes — let’s break this down into both the technical composition and the carbon chain structure of castor oil, especially when refined for high-performance or racing applications.

🔬 Technical Composition of Castor Oil (Raw & Refined)

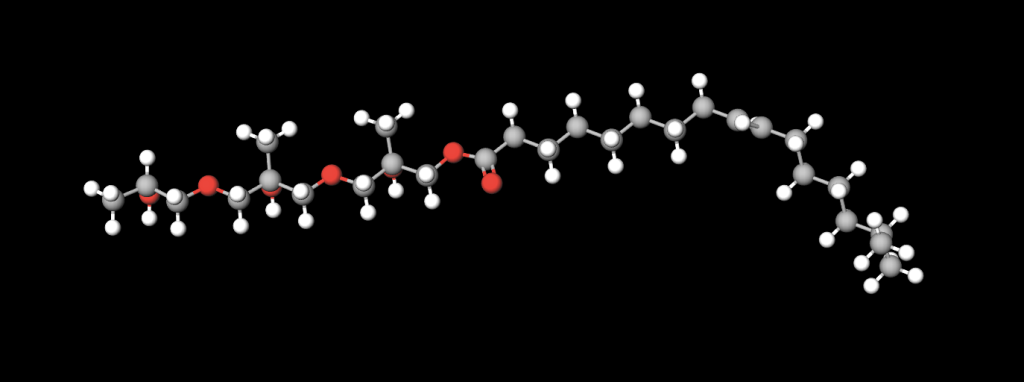

Castor oil is unique among vegetable oils due to its high content of ricinoleic acid, which has functional groups that give it both polar and non-polar characteristics—critical for lubrication.

🔹 Raw Castor Oil Profile:

| Component | Typical Content (%) |

|---|---|

| Ricinoleic acid (C18:1-OH) | 85–90% |

| Oleic acid (C18:1) | 3–5% |

| Linoleic acid (C18:2) | 3–4% |

| Stearic acid (C18:0) | ~1% |

| Dihydroxystearic acid | Trace |

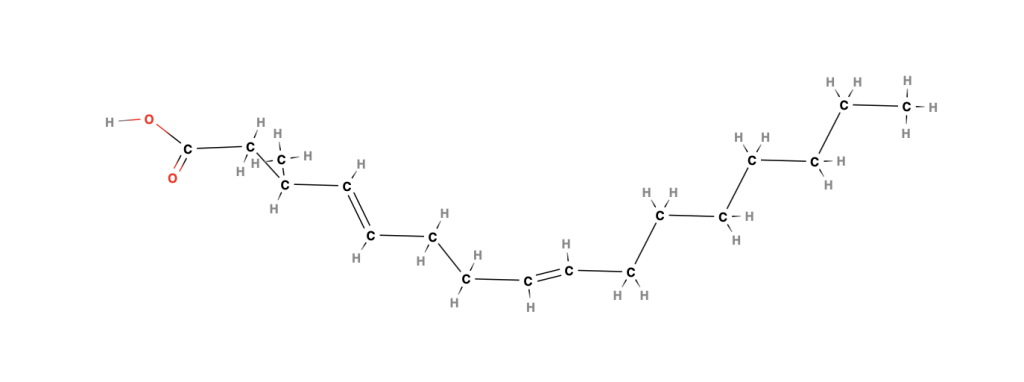

🧪 Ricinoleic Acid Molecular Structure

- C18 backbone, but with:

- One cis double bond at C9=C10

- One hydroxyl (-OH) group at C12

- This structure gives it:

- Hydrogen bonding capability

- High viscosity index

- Exceptional film strength

⚙️ In Racing Applications

When formulated into castor-based racing oil, several processing steps enhance its thermal and oxidative stability:

1. Dehydration → Dehydrated Castor Oil (DCO)

- Removes water to create conjugated double bonds

- Improves oxidative stability

2. Esterification (for synthetic esters)

- Forms ricinoleic esters, such as:

- Trimethylolpropane tri-ricinoleate (TMPTE)

- Pentaerythritol tetra-ricinoleate

3. Blending with esters or synthetics (for modern racing blends)

- Sometimes paired with PAO, esters, or alkylated naphthalenes

- Adds cleaner burn, low sludge, and improved cold flow

🧬 Carbon Chain Summary in Castor Racing Oils

| Oil Type | Main Carbon Chain Length | Functional Groups | Stability Use Case |

|---|---|---|---|

| Ricinoleic Acid | C18 | OH at C12, Double bond at C9 | Natural, high film strength |

| Dehydrated Ricinoleic | C18 | Conjugated C=C bonds | Better oxidation resistance |

| Synthetic Ricinoleate Esters | C18 x 3 or x 4 | Multi-branch esters | Used in high-temp racing & aviation oils |

🔥 Why It Works in Racing

- Handles temperatures over 260°C (500°F) without breaking down.

- Builds persistent lubricating films under load.

- Used in 2-stroke racing, rotary engines, and vintage race cars.

- Still favored in some karting and top fuel drag racing blends today.

Leave a Reply